Plumbing systems are essential throughout the world, from the transportation of freshwater and wastewater to their use for electricity. And because of their application in various industries, you can be overwhelmed by the choices available to you.

But ideally, you’d want to get your hands on more durable and easier-to-install materials for initial plumbing work to reduce installation time.

To help you out, here are 6 essential factors to consider when buying plastic pipes.

1. Type of pipe and water

Before buying a plastic pipe, there is only one place to start, and that is with the type of plastic. People are often surprised to discover the tremendous variety of options available to them. Nevertheless, it is essential to choose the right plastic for your system.

You usually have a choice between chlorinated polyvinyl chloride (CPVC), polyvinyl chloride (PVC), polybutylene (PB), or polyethylene (PE). You then have tubes made of PFA, which is a type of fluoropolymer.

PE, PB, and PFA are ideal for chemical systems or for anyone needing to transport corrosive or gaseous materials. These are also the perfect option for high-temperature materials, such as those used in oil and gas, pharmaceuticals, engineering, procurement and construction (EPC), and other industries.

Besides, CPVC plastic is the best choice for anyone who needs to transport water with their system. The ideal temperature for CPVC pipes is 150 to 180 degrees Fahrenheit.

And finally, we have PVC pipes, which are perfect for drainage, waste disposal, or ventilation. As far as temperature is concerned, PVC is suitable for transporting water at a temperature between 120 and 150 degrees.

Moreover, the water in your pipes can also be corrosive. Corrosive water refers to water that dissolves the materials it comes in contact with. Usually, it is water with a low pH value (acidic) that can lead to your pipes getting corroded faster.

Local water treatment plants that use chloramine (chlorine and ammonia mixture) instead of chlorine to treat the water supply can also contribute to faster pipe corrosion.

2. Exposure to sunlight

The sun has the same effect on the pipes as it does on our skin. Ultraviolet (UV) rays deteriorate plastic pipe surface quality over time, making them more vulnerable to problems and shortening their lifespan. Excessive exposure to the sun can also cause problems related to temperature changes.

For example, PVC pipes are used to carry cold water, so installing these in areas where temperatures are naturally high is not recommended. Many plumbers use insulating materials to prevent temperature fluctuations from affecting the pipe quality to combat this.

3. Plumbing use

The amount of water pressure you need is another determining factor in finding the right plumbing poly pipe fittings for your property.

If you’re looking for a plumbing solution in a commercial space, chances are you’re looking for high water pressure. To maintain high water pressure, your plastic pipe will need to be wide and durable enough to withstand substantial force.

If you’re looking to reduce operating costs, you should also consider the softness of the pipe. A smooth interior improves water flow, which reduces resistance and, therefore, the amount of water you need.

4. The thickness of the pipe

The thickness of the plastic is a significant factor to consider. Fortunately, it shouldn’t be too difficult to determine the thickness of your plastic pipes. Simply ask yourself the following two questions:

- How often will the system be used?

- What is the approximate volume of material that will pass through the system?

This will help you determine the pipe thickness you need. The more the system is used and the greater the volume of material, the thicker the plastic needs to be.

For example, the thickness and configuration of PVC pipe will vary depending on the application for which it is intended.

Picture this: Pressurized water pipes are not the same as sewer pipes or those used in stormwater drainage systems. Plastic plumbing products destined for potable water applications are generally classified as NSF-61 or NSF-PW to indicate that the product meets the health effects requirements of NSF/ANSI 6.

The NSF standard is a set of water treatment standards that establish strict requirements for controlling materials that come into contact with drinking water.

If you are unsure of the pipe thickness you need, it is always better to overestimate than underestimate. You can also reach out to a plastic pipe manufacturing company to get expert advice.

5. Soil characteristics

The composition of the soil that surrounds your pipes has a significant effect on their durability. Soil containing excess rock, moisture, and abrasive materials will eventually degrade your pipes faster.

It is also vital to examine the chemical composition of the soil. Sometimes soil containing an excess of minerals can create a reaction when it comes into contact with certain pipe materials.

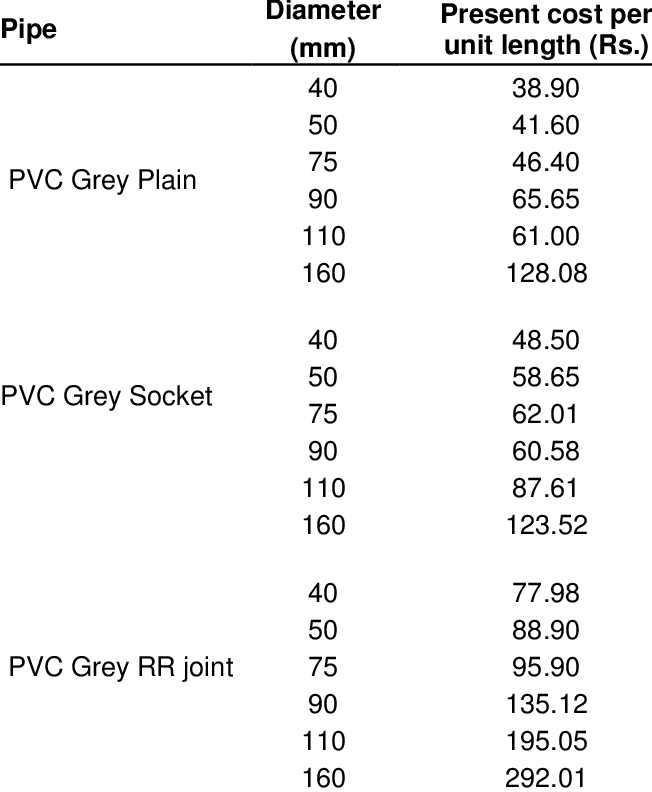

6. Cost of the pipe

Cost is always an essential element to consider when purchasing anything. However, it should certainly not be the determining factor when it comes to plastic piping systems.

The last thing you want is to buy a particular set of plastic pipes just because they are the cheapest, as this may indicate a lack of quality.

Instead, make sure you invest in good quality plastic pipes and fittings to make sure you don’t waste money on repairs and maintenance down the line.

So look for a supplier that offers quality plastic pipes at a reasonable price. Do a little research and read the reviews left by previous clients to find out what they say about the products they received, the service, etc.

Purchase the right pipes for your project

How many times in your life will you make a choice that others will have to live with for 50 years or more? There are probably very few circumstances that come to mind. However, that’s exactly what you do when choosing a pipe material because choosing the wrong material can have significant financial consequences.

Pipe purchases should be made with longevity in mind. Start by understanding the variables and choose the material(s) accordingly, taking into account the above elements.

Remember that one size does not fit all, and your responsibility is to consider all conditions today to select the best solution for tomorrow.